Objectives

ΣIDERWIN project aims at developing an innovative electrochemical process to transform iron oxide into steel metal plates. This process, based on the ULCOWIN technology developed since 2004, produces steel by electrolysis without direct CO2 emissions. In this operation, electrical energy and iron oxide are converted into chemical energy consisting of separated iron metal from oxygen gas. It is a disruptive innovation that entirely shifts the way steel is presently produced.

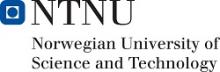

Electrolysis is the main processing unit of an iron-making route beginning with mineral iron ore and producing liquid steel.

Electrochemical processing route for steel production and ULCOWIN technology to decompose iron oxides

The new technology will contribute to the achievement of the strategic goals defined by the European Commission for Europe 2020. Full deployment of such technology will deliver significant contributions to European Union objectives of CO2 emission reduction, of energy efficiency improvement, of increased share of renewable energy and of material resource efficiency.

Furthermore, as a breakthrough technology addressing the processing route of a large and energy intensive industry it would fully participate into several flagship initiatives such as the “Innovation Union”, “Industrial Policy for the Globalisation Era”, “Resource efficient Europe” and “Agenda for new skills and jobs”.

Main Objectives

The consortium has set five main objectives:

The first objective is to develop, build and demonstrate the production of iron metal from its oxide without direct involvement of carbon or fossil fuels and according to the simplest stoichiometry of the reaction of iron oxide decomposition:

½Fe2O3 -> Fe + ¾ O2

The second objective is to produce iron by electrowinning with a prototype cell equipped with the key components of the final version.

The third objective is to interface the electrowinning prototype cell with a communication system to operate it according to electric grid priorities in real time.

The fourth objective is to produce iron metal from iron oxide coming from low-grade iron ore incompatible with the conventional process and from residues of non-ferrous metallurgies.

The fifth objective is to propose a profitable model that should facilitate the financial support of the next development steps of the ULCOWIN process. Thus, bridging the “valley of death” between TRL 6 and 8 where investment is too high for research programs and too risky for industrial participation.

Specific objectives of ΣIDERWIN project

Background

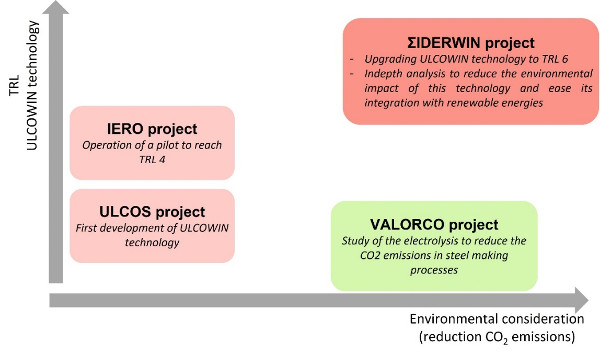

ΣIDERWIN project takes over the ULCOWIN part generated from the ULCOS and IERO projects. The objective is to go one step further than both the IERO and the VALORCO projects in order to provide a TRL 6 demonstrator in the form of a 3 metre-long pilot answering the need to reduce the CO2 emissions in the steel industry and easing its integration with RES.

Complementarity between the different projects